|

Wind Turbine Speed Control Systems

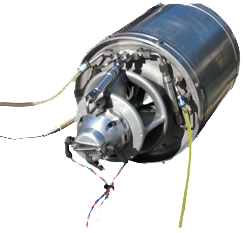

We refurbish Vestas Rotor Current Controller (VRCC) electronic speed control systems for giant wind turbines. The device insures that the turbine is maximizing its power output while remaining “in phase” with the 60 cycle transmission lines. Rotor Current Controllers are subject to harsh working conditions, and eventually fail. Wind farms lose a significant amount of revenue each day turbines are shut down for repair. We try to minimize that time with our product and service.

Orbital Machine Works creates a fully refurbished product. This is one of ways we separate ourselves from competitors who choose less reliable replacement methods. We also choose to work hands on with our customers to troubleshoot any issues they have. Because of our experience with the system, we also helped Florida Light and Power solve an issue they had been chasing for several years (FPL is a national electrical power company with many wind power farms within the USA). They were experiencing an occasional oscillation, or bucking motion, in their wind turbine transmissions. Our experience and data collected from repairing previous units allowed us to complete a mathematical analysis of the turbine's performance. It was determined that the issue was caused by a component program ignoring the effect of wind gusts as the turbine approached maximum power. These wind gusts would eventually cause the generator to crossover the power curve in these situations and act as a motor instead of a generator. A minor programming adjustment solved the problem. FPL saved a great deal of wear and tear on their massive and turbine transmissions, and in turn, significant down time and repair costs.

|

|

|